Description

Systems, applications, and components

We specialize in Consulting, Design, and Production of essential components for Controlled Contamination Environments.

Mobile wall system

Our modular mobile walls are designed for flexibility, cleanability, and structural integrity in sensitive environments.

Key Features:

- Surface Material: 4 mm thick HPL (High Pressure Laminate). Class F1 laminate, available in various colours and finishes.

- Structure: Internal frame made of proprietary tubular aluminium alloy profiles, assembled via electro-welding.

- Cavity/Core: Filled with self-extinguishing Class 1 sintered expanded polystyrene (closed cells, UNI 6349-68 standards) or non-combustible aluminium honeycomb.

- Assembly: Components are high-pressure hot-pressed using high-strength adhesive.

- Flexibility & Maintenance: Unique vertical junction profile allows for the DISASSEMBLY of every single panel, regardless of its position.

- Installation Optimization: The system is designed for total independence of the false ceiling from the floor perimeters, allowing mechanical and electrical engineers to operate freely and optimize installation times.

Connecting & radius profiles

We provide specialized aluminium profiles to guarantee perfect coplanarity and sealing at all critical junctions—essential for cleanroom compliance.

Anodized-painted against profile

Creates a radiused connection point (wall–wall, ceiling–wall, wall–floor). Components include a 70 mm radius cove molding.

Monolithic profile to be cladded

Special floor and ceiling profiles designed to achieve coplanarity between wall and floor, prepared to receive PVC cladding. Features a 70 mm radius and a compensation ruler for adjusting to uneven flooring.

Coved skirtings against

Extruded, anodized aluminium profile with a 70 mm radius, applied against intersecting surfaces (wall–wall, floor–wall, ceiling–wall).

Coplanar radiused profiles (milled cove molding)

Special anodized aluminium profiles (70 mm radius) applied directly to the mobile wall frame to ensure the junction point between the radius profile and the laminate is perfectly COPLANAR.

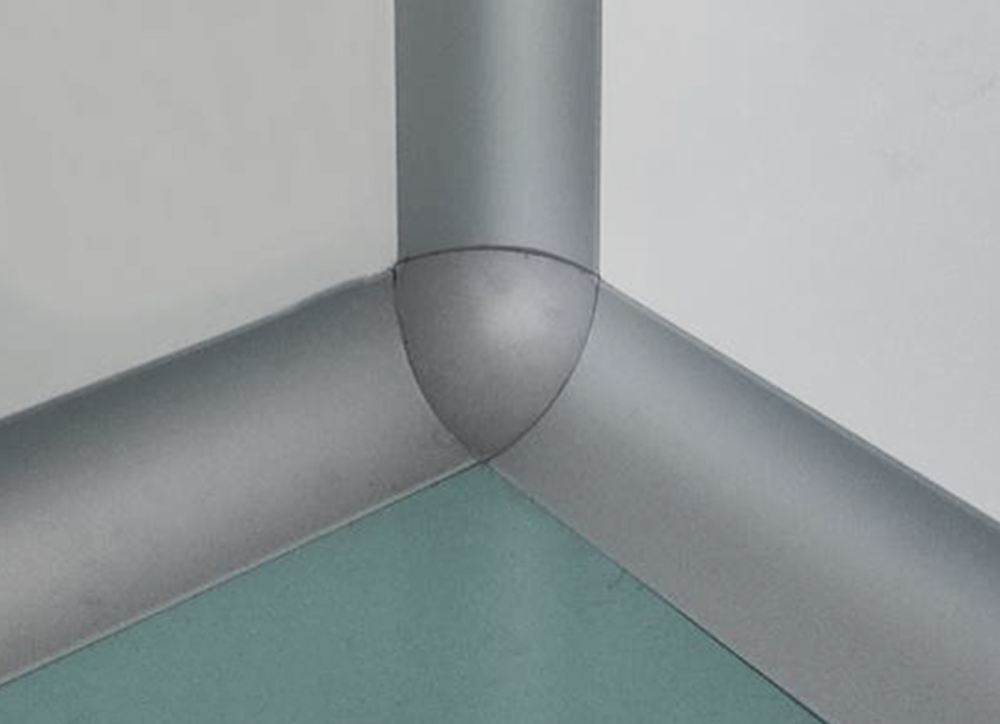

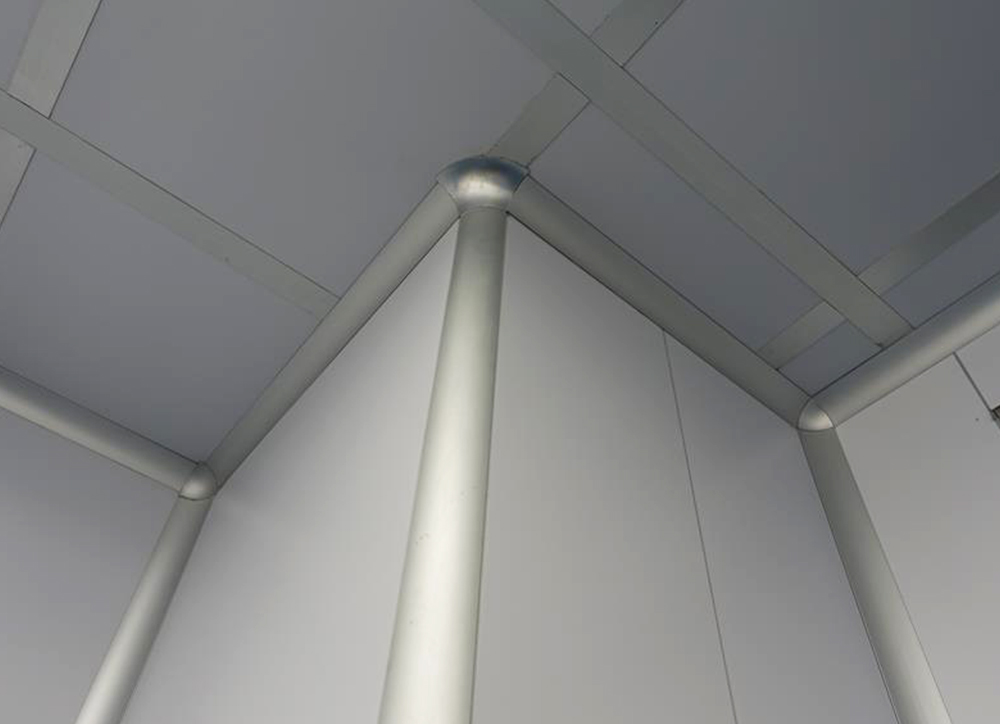

Perimetral junction details

Specialized aluminium details (to create “EIGHTHS” and “QUARTERS” of a sphere) needed to connect floor/ceiling perimeters with the mobile wall vertical profiles, ensuring perfect coplanarity for both exposed and cladded solutions.

Fan filter units

Indipendent Filter Fan Unit designed for Cleanrooms in areas where hazardous, inflammable atmospheres can be present. The AIR-1-EX Filter Fan Units are equipped by elettrofans in compliance to the directive 94/9/EU (ATEX), standard like prEN 14986:2004 (D), DIN EN 13463-1 and DIN EN 60079-14 have been taken into consideration: therefore they can be used were hazardous, inflammable atmospheres only arise occasionally (zone 1 and 2).

Pharma-type doors

Doors specifically engineered for controlled contamination environments.

Pharma-type doors

Doors specifically engineered for controlled contamination environments.

Swing Doors

- Application: Incorporated doors for controlled contamination environments.

- Structure: Frame made of UNI 3569 TA 16 aluminium alloy (45 mm section) with rounded stops and edges.

- Leaf: 4 mm thick HPL stratified laminate, Class F1, with either self-extinguishing polystyrene or non-combustible aluminium honeycomb core.

- Closing System: Secure closure achieved via magnetic bars inserted into the aluminium frame stops.

- Hardware: Two-winged hinges (Dorma or similar) with millimetre adjustments; fixed satin stainless steel knobs.

Sliding Doors

- Application: Internal doors for controlled contamination environments.

- Leaf/Core: Same HPL laminate and core options as swing doors.

- Mechanism: Aluminium guide with relative carriages ensures perfect functioning.

- Features: Recessed Teflon handle for manual opening. Option for installing sliding leaf automation.

Grid ceilings

Modular systems designed for clean environment specifications.

- Tiled False Ceilings: Modular 600 x 600 mm or 600 x 1,200 mm tiles. Constructed with “T” section aluminium profiles (64 mm visible surface) and suspension hangers. Infill panels are 4 mm stratified laminate or 6 mm thick Compocel H (aluminium honeycomb core).

- False Ceilings with Light Channels: Modular system (600 mm pitch) utilizing “T” section aluminium profiles for suspension. Uses 40 mm thick sandwich panels with double pre-painted steel sheet and a polyurethane cavity.

- Walkable False Ceilings with Light Channels: Mentioned as an available product.

Furnishings

Essential accessories for sterile area changing rooms and material transfer.

Gown Lockers

Custom-sized doors in rounded laminate, concealed hinges, lock with key, personalized numbering, and stainless-steel gown hanging rails.

Ventilated Gown Lockers

Monobloc units for storing staff gowns and shoes. Features a suction grid in the upper part allowing “washing” with treated air coming from the sterile room.

Ventilated Material Pass Box

Horizontal passages for materials/equipment between adjacent rooms. Includes hinged doors with safety double glazing or laminate, magnetic bar closing system (prepared for mechanical interlock), and micro-perforated stainless-steel shelves for air exchange.

Benches

Acts as a barrier physically delimiting the “clean” area. Available with aluminium/laminate structure or entirely in stainless steel. Designed with internal compartments to optimize space for shoe storage.

Sanitizers

Electronic hand sterilization system integrated coplanar to the mobile wall, housed within a dedicated technical compartment in the entrance changing rooms of sterile areas.

Vision Panels

45 mm thick double glazing (6/7 + 31.5 + 6/7 composition). Applied coplanar with silicone sealing after panel drilling (pantograph). Available with corner radii of R=10 mm or R=100 mm.