Description

Product Description

Additional Devices

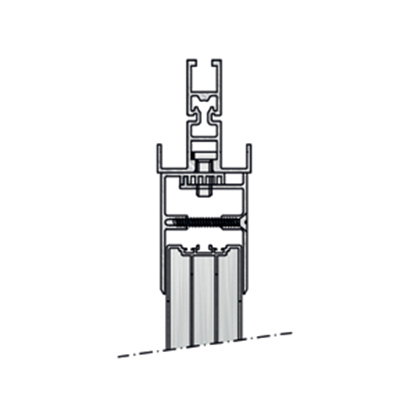

Wall clamping track

Double clamp-fastened profiles in anodised extruded aluminium, fixed to the filter-holder grid by hammerhead screws.

Slot closure profile

Anodised aluminium profile for closure of the slot of the profile: click-in insertion.

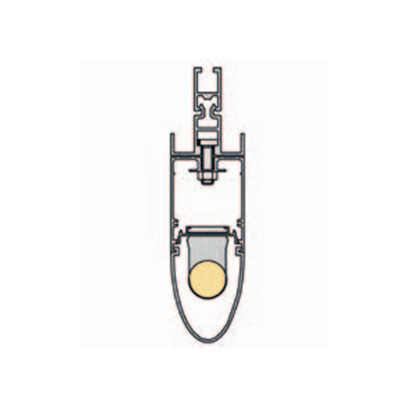

Teardrop light

Teardrop light with aerodynamic profile specially designed for use in controlled contamination environments.

Profile for plenum

Profile in anodised aluminium to support the housing surrounding the plenum.

Sprinkler head

Flexible stainless steel braided hose connected to a one-piece sprinkler drop with grid attachment and quick response sprinkler head.

Installation Typologies

Profile

Blank Panels

Applications

Cleanrooms for the Microelectronic, Electronic, Optical, Mechanical, Aerospace and Pharmaceutical industries.

Components’ description

Construction

they consist of three screwed together made of sturdy sheet steel box structures, painting RAL 9010, thickness

1.0-1.5 mm, constructed, assembled and reinforced to prevent mechanical resonance of the unit.

Radial electric fan,

with an EC electric motor, coupled directly to an aluminium rotor with inverted blades.

Flat disposable pre-filter

G4 class in compliance to EN 779 standard.

Absolute filter,

with low pressure drop, H14 class, in accordance to EN1882:2009

Nozzles

adjustable in aluminium or PVC, on request, with polyurethane gasket, located:

- at the side: in coloumns;

- on the upper part: in ceiling

Doors

made of a study natural anodised aluminium frame with two VISARM 3+3 smash–proof sealed glass units.

Lighting

by means of fluorescent light fitted in sealed fixtures on the ceiling of the Air Shower.

Electrical Panel

incorporated in the Air Shower, it contains all the necessary instruments for commanding, controlling and protecting the Air Shower.

Signalling panels

Light panels installed near the entrance and exit doors for indicating the operating status of the Air Shower

Alarm

if a person enters or leaves the Air Shower during the shower phase or if the two doors are simultaneously opened,

thus connecting the Cleanroom with the adjacent room, the alarm buzzer comes on. PTFE type U15 efficiency in compliance to EN 1882 standard.