Description

Product Description

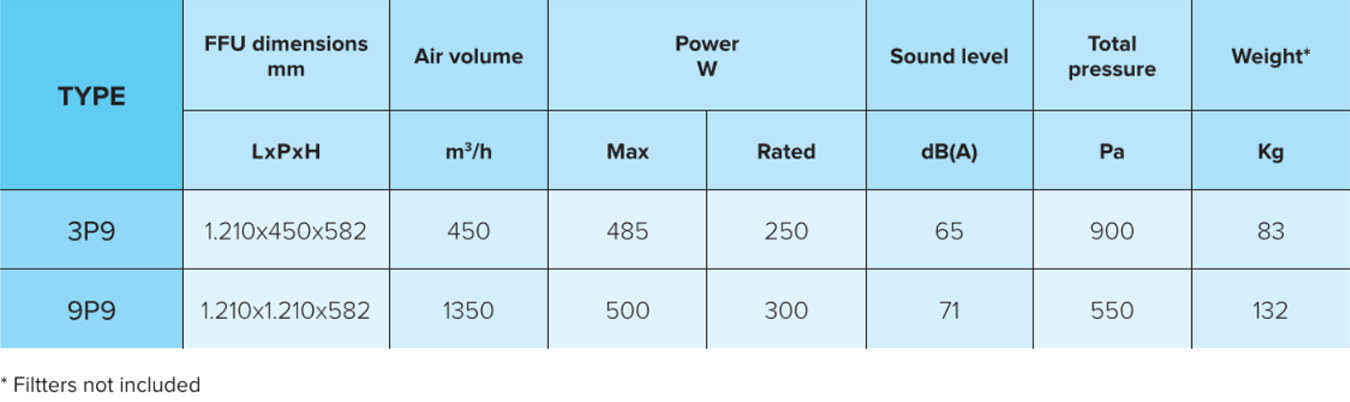

Technical Data

Applications

Isolators and Laminar Flow Systems for Food & Beverage Industries.

Components’ description

Caisson container

in stainless steel sheet AISI 304 thickness 12/10, sturdy construction, reinforced at critical points to prevent mechanical resonance of the whole.

Flat disposable pre-filter

G4 classe in accordance to EN779:2012 standard.

Centrifugal electric fan

with an EC electric motor, coupled directly to an aluminium rotor with inverted blades.

EC Controller

built into the fan to action, control and regulate it.

Absolute filter

with low pressure drop, EN 1882 class.

Diffuser splash guards

in stainless steel AISI 304

Electrical panel

built into the unit to action, control and protect it.

Lighting

by means of waterproof ceiling light built-in the Unit.

Optional accessories

Pocket filter

class F7, to EN779:2012 standard, complete with

stainless steel filter holder; with this accessory the unit measures 660x445x910

3P9: 1210x450x932 – 9P9: 1210x1210x932