Description

Product Description

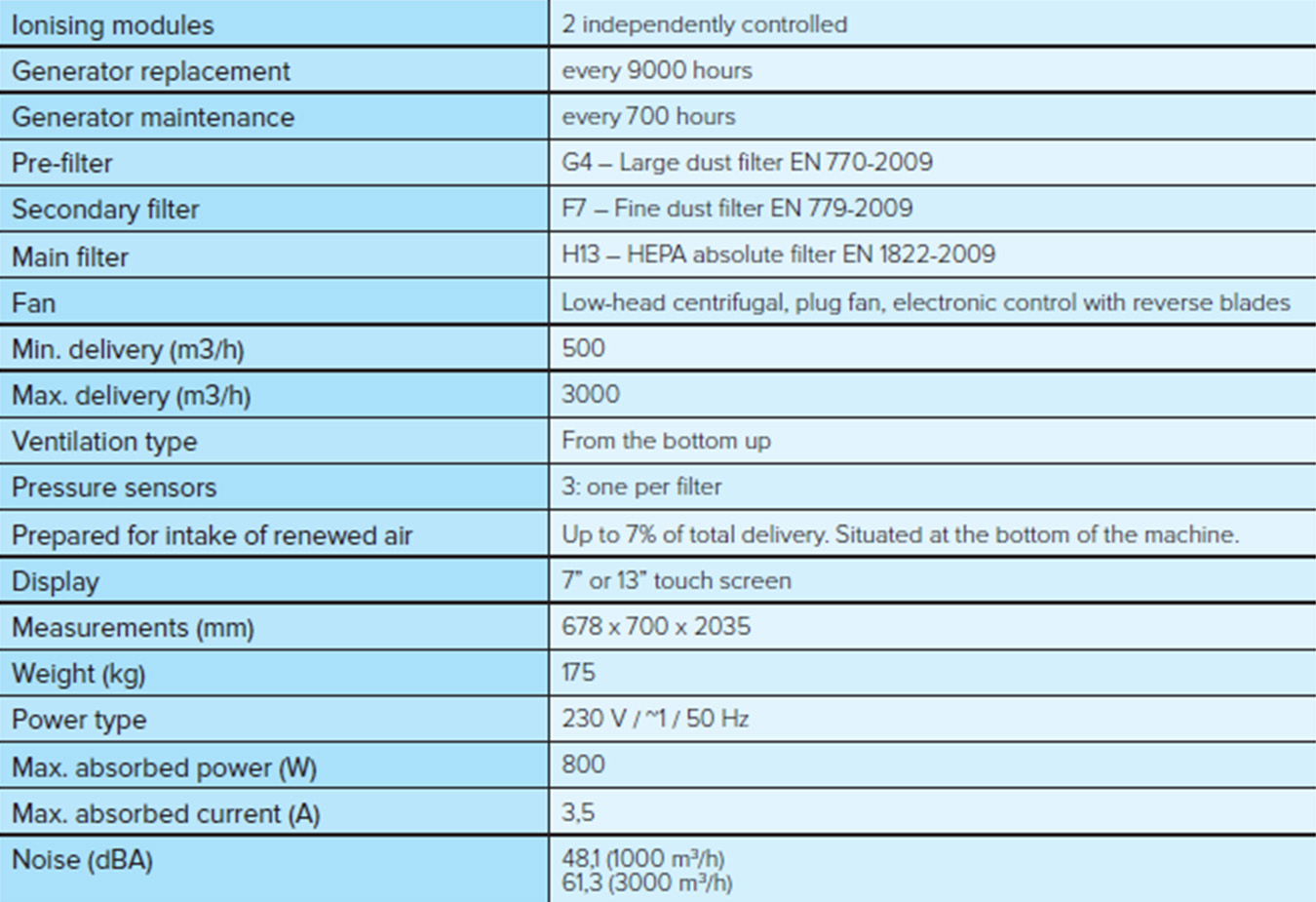

Technical Data

NTP Technology non thermal plasma

NTP is a cutting edge oxidation process to decontaminate indoor air using NON THERMAL PLASMA. DepOne air sanitizing devices using NTP Technology (Non Thermal Plasma) are used for the purpose of sanitation and decontamination of air and surfaces.

The term plasma means a mixture of ionised gas containing a large amount of charged particles, like ions or electrons, free radicals, ros, molecules and even neutral atoms. Ionisation occurs when an electron acquires su cient energy to overcome the attractive force of the atom’s nucleus. When this result is obtained with processes that generate a plasma with the temperature of the ions and neutral atoms considerably lower than the electrons, we talk of cold plasma or Non-Thermal Plasma (NTP). Non-thermal plasma emits light with wavelengths in both the visible part and in the ultraviolet part of the spectrum. Besides the emission of UV radiation, an important property of cold plasma is the presence of highenergy electrons, highly reactive, which generate numerous chemical and physical processes such as oxidation, the excitation of atoms and molecules, the production of free radicals and other reactive particles. A plasma can be generated artifi cially by providing a gas with su ciently high energy, that is, by applying energy to a gas so as to reorganize the electronic structure of the species (atoms, molecules) and produce excited species and ions. One of the most common ways to artificially create and maintain a plasma is the use of an electrical discharge in a gas. In NTP technology, using the so-called non-thermal shocks with a dielectric barrier method. The ionization potential and the density of the charged species generated from the plasma with a barrier electric discharge (BDB) are greater than those present in the non-thermal plasma generated from other systems.

Certifications

depOne JONIX INSIDE is a Class 1 Medical Device, EC Directives

93/42/CE, 2006/42/CE, 2006/95/CE, 2007/108/CE, CND

Z12159099

Registration n. 1329272

Made in Italy

Designed and made by expert professionals in air purification in health environments.

The device is designed to be both robust and easy to handle.

Ecological and compatible with people presence

No chemical products used and zero environmental impact. It enables reducing the volumes of air processed by the centralized

plant and therefore reduces air conditioning costs.

Ecological Design

Eco = No chemical products

It can be used during any health related interventions.

Its continuous running, in addition to air sanitization, will generate a proper air ionization that provides environmental comfort to

help reduce work-related stress, aiding respiratory functions, as part of the protection and promotion of health in the workplace.

Logic = User Friendly

depOne is simple and intuitive, the touch screen is used to set and control the functions, to consult the usage status of the perishable components. With a view to integrated plant management, the controls and functions can be managed remotely.

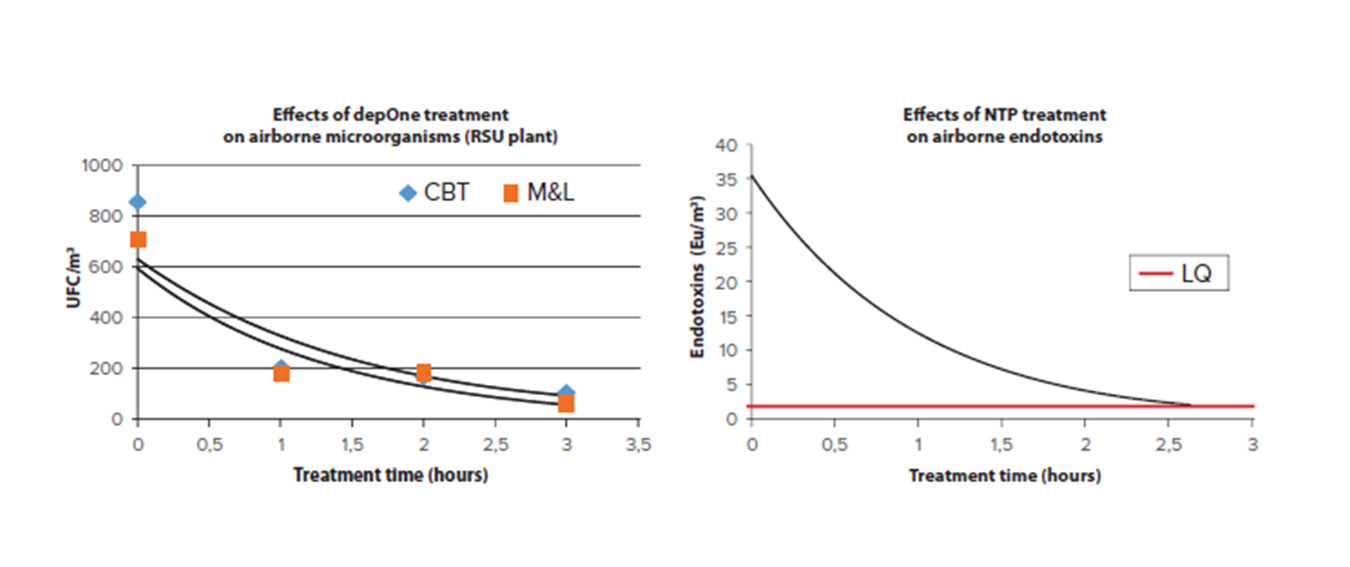

Effective

The biocidal activity and neutralization of polluting substances takes place in a maximum of 120 minutes from power on. The continuous operation of the device prevents the spread of biopollutants generated continuously during the health activities.

The oxidation process of the microorganisms is carried out by oxidation of the cell membrane. Reactive particles that carry electrical charges, among which the most important are the reactive oxygen species (e.g. atomic oxygen and ozone), which concentrate on the surface of the membranes causing their destruction.

The device is e ective on: gram + and – bacteria, moulds and yeasts, viruses, bacterial endotoxins, VOC (volatile organic compounds), smells.

depOne eliminates all odours of an organic and chemical origin.

Reactive particles break down the chemical bonds of the odorous substances, decomposing them.

Application Fields and Function Cycles

The device can be used in high concentration points of people in hospital rooms, laboratories, clinics, operating theatres.

The operation may be continuous or in cycles according to the specific needs.

Environmental decontamination cycle vol. 800 mc 120 minutes.

Environmental decontamination cycle vol. 150 mc 60 minutes.

Environmental decontamination cycle vol. 50 mc 30 minutes.

Continuous cycle of sanitization – set the air fl ow 20 times higher than the ambient volume.