Description

Product Description

Applications

Cleanrooms for Microelectronic, Electronic, Optical, Mechanical, Aerospace, Food, Pharmaceutical and Medical industries.

Components’ description

Box shaped structure

in strong 12-15/10 mm thick steel plate, painted in the required RAL colour, adequately strengthened to block any mechanical resonance.

Neoprene sealing gaskets

between the box structures and panels

High-head centrifugal electric

fans, with a three-phase electric motor directly coupled to reverse blade impellers in galvanised steel and galvanised screw feeder.

Flat disposable pre-filter

G4 class in compliance to EN 779 standard.

Pocket filters

F9 class in compliance with the EN779 standards, complete with stainless steel filter-holder housing

Adjustable aluminium nozzles

with polyurethane sealing gasket.

Automatic rapid folding doors formed

of a strong painted steel structure and PVC canvas doors, complete with automation system, command and safety devices and balancing system.

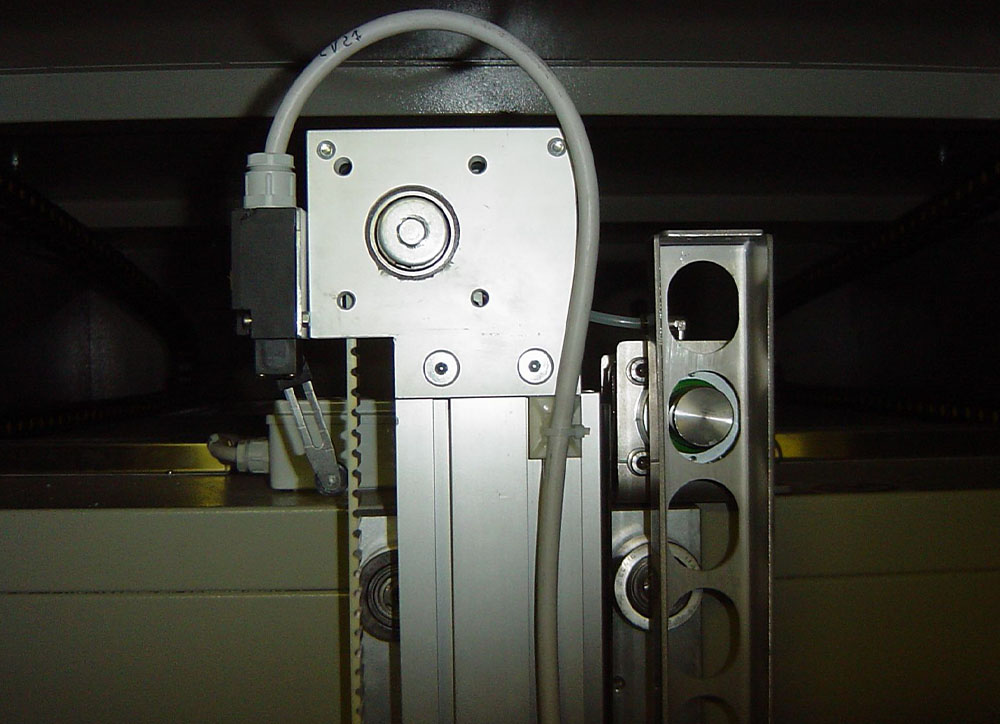

Superior plenum automation

formed of aluminium and steel motorised runners, cogged anti-stretch belt, trolley and worm screw geared motor, complete with three-phase electric motor.

Internal fluorescent lighting

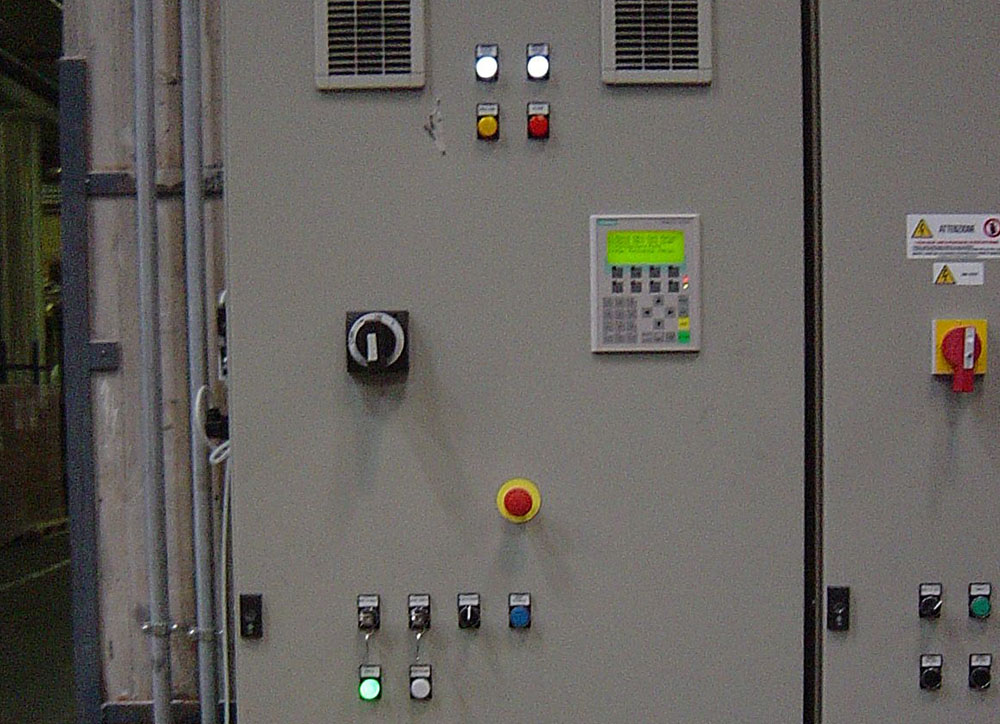

Electric board

supplied separately in a painted steel cabin, which contains all the command, control and protection equipment for the Dust Exhaust.

PLC

for managing the Dust Exhaust function logic.

Differential manometers

for detecting whether the pre-filters and pocket filters are blocked.

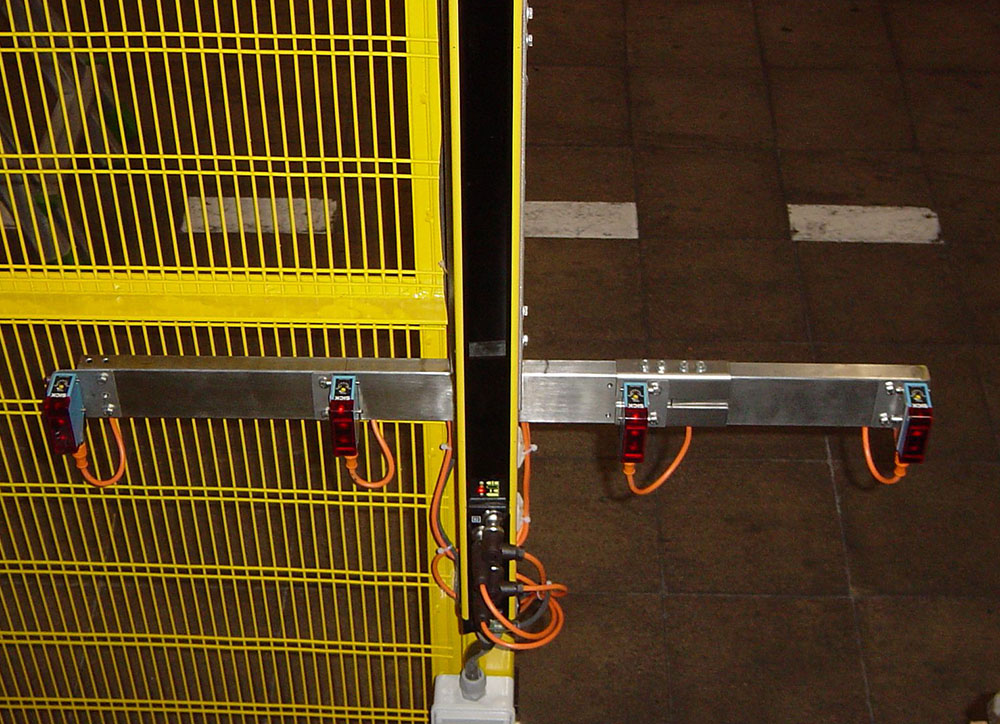

Safety barrier

a device to detect and distinguish the material that is entering the Dust Exhaust.

Anti-falling device

a mechanic/pneumatic safety device which blocks the Dust Exhaust ceiling.

Operator control panel

all the useful information are shown on the operator control panel.

Optional accessories

Absolute filter

with low pressure drop, available with H10, H12 or H14 class, in accordance to EN1882:2009.